Case Studies

Springboard Pro Limited

Springboard Pro Ltd of Cambridge, had an application that warranted ultra-high frame rates. They wanted to study in detail the movement of a small spring loaded mechanism. The Photron SA-X2 mono high speed camera was allocated for this purpose. Delivery and training was provided on the day. It was set up to record at 100,000 fps at 200 x 512 resolution. It was externally lit using a powerful LED floodlight also provided by Slowmo.

Springboard Pro Ltd of Cambridge, had an application that warranted ultra-high frame rates. They wanted to study in detail the movement of a small spring loaded mechanism. The Photron SA-X2 mono high speed camera was allocated for this purpose. Delivery and training was provided on the day. It was set up to record at 100,000 fps at 200 x 512 resolution. It was externally lit using a powerful LED floodlight also provided by Slowmo.

The camera proved highly successful in a long term, month by month quantitative analysis. It provided clear images which were valuable to the further design and testing of the mechanism. Slowmo was able to provide a rolling rental agreement for Springboard at a competitive rate so that they could use the camera equipment without any hire duration restrictions.

FPT Industries

Slowmo was first hired by FPT Industries (part of GKN Aerospace) back in 2007 to film drop tests of a new helicopter fuel tank. In order to pass relevant industry standards, the fuel tanks were dropped from a height of 50ft and the high speed images were used to determine possible failure modes. Since then Slowmo has filmed over a dozen more drop tests.

Slowmo was first hired by FPT Industries (part of GKN Aerospace) back in 2007 to film drop tests of a new helicopter fuel tank. In order to pass relevant industry standards, the fuel tanks were dropped from a height of 50ft and the high speed images were used to determine possible failure modes. Since then Slowmo has filmed over a dozen more drop tests.

The early trials were covered by a single camera (Photron APX). Now, it is standard to provide 4 views of the tank at ground impact at a frame rate of 1000fps. Four Photron cameras (all powered from 24V lithium Ion batteries) are linked via an Ethernet hub to a single laptop computer showing simultaneous live views from all 4 angles. This allowed the customer to approve the framings before the trial began. Playback of the drop test was provided immediately after the trial was completed.

Bladon Jets Ltd

Slowmo was asked to provide expertise and a camera for filming the inside of a small gas turbine combuster. One of main requirements was to determine the flow characteristics of a conical fuel spray.

Slowmo was asked to provide expertise and a camera for filming the inside of a small gas turbine combuster. One of main requirements was to determine the flow characteristics of a conical fuel spray.

When filming sprays, a fast shutter speed is required in order to see the individual particles. A consequence of increasing shutter speed is an increase in the light required. The ultra-sensitive Photron SA-X2 high speed camera was therefore chosen and a powerful LED floodlight used to illuminate the test rig. A frame rate of 10000 fps together with a shutter speed of 1/100,000s provided detailed images of how the fuel spray formed and the flow direction of the individual fuel particles. Further trials involved the filming of the ignition phase.

Mark from Slowmo set up the camera, lighting and provided training. The equipment was then dry hired for the rental period.

Energy Technology Centre

Slowmo was contacted by the Energy Technology Centre, based in East Kilbride, in order to provide high speed images of a new test rig used to investigate the impact between wind turbine blade test samples and rain droplets. The rig consisted of an arm rotating at 2000rpm and footage was required of the arm tip striking a falling water droplet.

Mark from Slowmo visited the site and set up a Photron SA-X2 mono high speed camera together with a powerful LED floodlight. With this setup, the rotating arm was recorded at 40000fps (shutter speed 1/266666s). This showed in great detail the position and impact characteristics of each water droplet hitting the arm tip. Training was provided and the equipment left in position for an extended dry hire rental period.

Tension Technology International

As part of an ongoing investigation Slowmo was asked to film a break test on two fibre rope assemblies attached in tandem. The two ropes had different extension characteristics and their reaction up to and after failure was required. The tests were to take place in Rotterdam.

As part of an ongoing investigation Slowmo was asked to film a break test on two fibre rope assemblies attached in tandem. The two ropes had different extension characteristics and their reaction up to and after failure was required. The tests were to take place in Rotterdam.

Due to the long lengths of the ropes (~20m), Slowmo travelled over to Holland with 3 x high speed mono cameras (Photron SA-X2, SA5 and SA3) in order to cover the potential points of failure. LED floodlights were used to illuminate key areas of the test.

The SA-X2 and SA5 cameras were set to record at 5000 fps and the SA3 at 2000fps. Each camera was put on a centre trigger and all linked via BNC cable reels to single thumb switch, which allowed triggering from a safe distance.

Important images showing failure characteristics were recorded from 3 trials.

Hitachi Rail Europe

The interaction of a high speed train pantographs with overhead lines is an important area within the rail industry. One particular trial required footage of the wave created by the contact force of the pantograph. Unusually regards high speed filming, the trial had to be done at night. Having previously worked on a similar day time trial, Slowmo Ltd was called on to provide the images.

The interaction of a high speed train pantographs with overhead lines is an important area within the rail industry. One particular trial required footage of the wave created by the contact force of the pantograph. Unusually regards high speed filming, the trial had to be done at night. Having previously worked on a similar day time trial, Slowmo Ltd was called on to provide the images.

The Photron SA-X2 mono high speed camera was the obvious choice for this application because of its industry leading light sensitivity. In order to illuminate the wires and pantograph, one of Slowmo’s powerful LED floodlights was used. As the floodlight is only rated at 200W (for 2KW tungsten equivalent) a small briefcase type generator was used for power. The camera was set low on a tripod, angled upwards towards the wires and a field of view of around 6m was set using a 50mm F1.4 lens.

With this night time set-up, amazingly a high speed train was able to be filmed at 2000 fps. Furthermore, the clarity within the image allowed one to easily assess the movement of the overhead wires as the pantograph passed underneath. Images over 3 consecutive nights were then recorded.

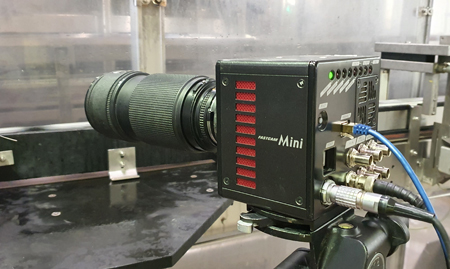

Slowmo has assembled a fully comprehensive, easy to use, dry hire package for industrial applications, where frame rates are in the region of 1000-5000 fps. Everything is included in the rental: AX-100 camera, laptop, lenses, tripod, lights and stands. A quick start guide will assist you through the basic operation.

Slowmo has assembled a fully comprehensive, easy to use, dry hire package for industrial applications, where frame rates are in the region of 1000-5000 fps. Everything is included in the rental: AX-100 camera, laptop, lenses, tripod, lights and stands. A quick start guide will assist you through the basic operation. Springboard Pro Ltd of Cambridge, had an application that warranted ultra-high frame rates. They wanted to study in detail the movement of a small spring loaded mechanism. The Photron SA-X2 mono high speed camera was allocated for this purpose. Delivery and training was provided on the day. It was set up to record at 100,000 fps at 200 x 512 resolution. It was externally lit using a powerful LED floodlight also provided by Slowmo.

Springboard Pro Ltd of Cambridge, had an application that warranted ultra-high frame rates. They wanted to study in detail the movement of a small spring loaded mechanism. The Photron SA-X2 mono high speed camera was allocated for this purpose. Delivery and training was provided on the day. It was set up to record at 100,000 fps at 200 x 512 resolution. It was externally lit using a powerful LED floodlight also provided by Slowmo. Slowmo was first hired by FPT Industries (part of GKN Aerospace) back in 2007 to film drop tests of a new helicopter fuel tank. In order to pass relevant industry standards, the fuel tanks were dropped from a height of 50ft and the high speed images were used to determine possible failure modes. Since then Slowmo has filmed over a dozen more drop tests.

Slowmo was first hired by FPT Industries (part of GKN Aerospace) back in 2007 to film drop tests of a new helicopter fuel tank. In order to pass relevant industry standards, the fuel tanks were dropped from a height of 50ft and the high speed images were used to determine possible failure modes. Since then Slowmo has filmed over a dozen more drop tests. Slowmo was asked to provide expertise and a camera for filming the inside of a small gas turbine combuster. One of main requirements was to determine the flow characteristics of a conical fuel spray.

Slowmo was asked to provide expertise and a camera for filming the inside of a small gas turbine combuster. One of main requirements was to determine the flow characteristics of a conical fuel spray.

As part of an ongoing investigation Slowmo was asked to film a break test on two fibre rope assemblies attached in tandem. The two ropes had different extension characteristics and their reaction up to and after failure was required. The tests were to take place in Rotterdam.

As part of an ongoing investigation Slowmo was asked to film a break test on two fibre rope assemblies attached in tandem. The two ropes had different extension characteristics and their reaction up to and after failure was required. The tests were to take place in Rotterdam. The interaction of a high speed train pantographs with overhead lines is an important area within the rail industry. One particular trial required footage of the wave created by the contact force of the pantograph. Unusually regards high speed filming, the trial had to be done at night. Having previously worked on a similar day time trial, Slowmo Ltd was called on to provide the images.

The interaction of a high speed train pantographs with overhead lines is an important area within the rail industry. One particular trial required footage of the wave created by the contact force of the pantograph. Unusually regards high speed filming, the trial had to be done at night. Having previously worked on a similar day time trial, Slowmo Ltd was called on to provide the images.