3D Digital Image Correlation (DIC) is an optical Computer Aided Engineering (CAE) method that makes use of stereoscopic technology to measure contour, deformation, vibration and strain of a target surface over time.

The surface is tracked by using a random surface pattern (commonly referred to as speckling). The technique can be used for many tests including tensile, torsion, bending and combined loading for both static and dynamics applications.

When the displacement/distortion occurs over a very short period of time, for example during fast impacts, explosive events, high speed cameras need to be used. Regards the specific camera requirements, they have to be synchronised to the exact frame and maintain a high resolution at high frame rates, whilst producing a good contrast of the speckling effect. A pair of matched lenses are also required. Mono cameras are preferred although good results can be obtained from colour sensors.

Slowmo Ltd has provided high speed cameras for several DIC experiments involving blast trials.

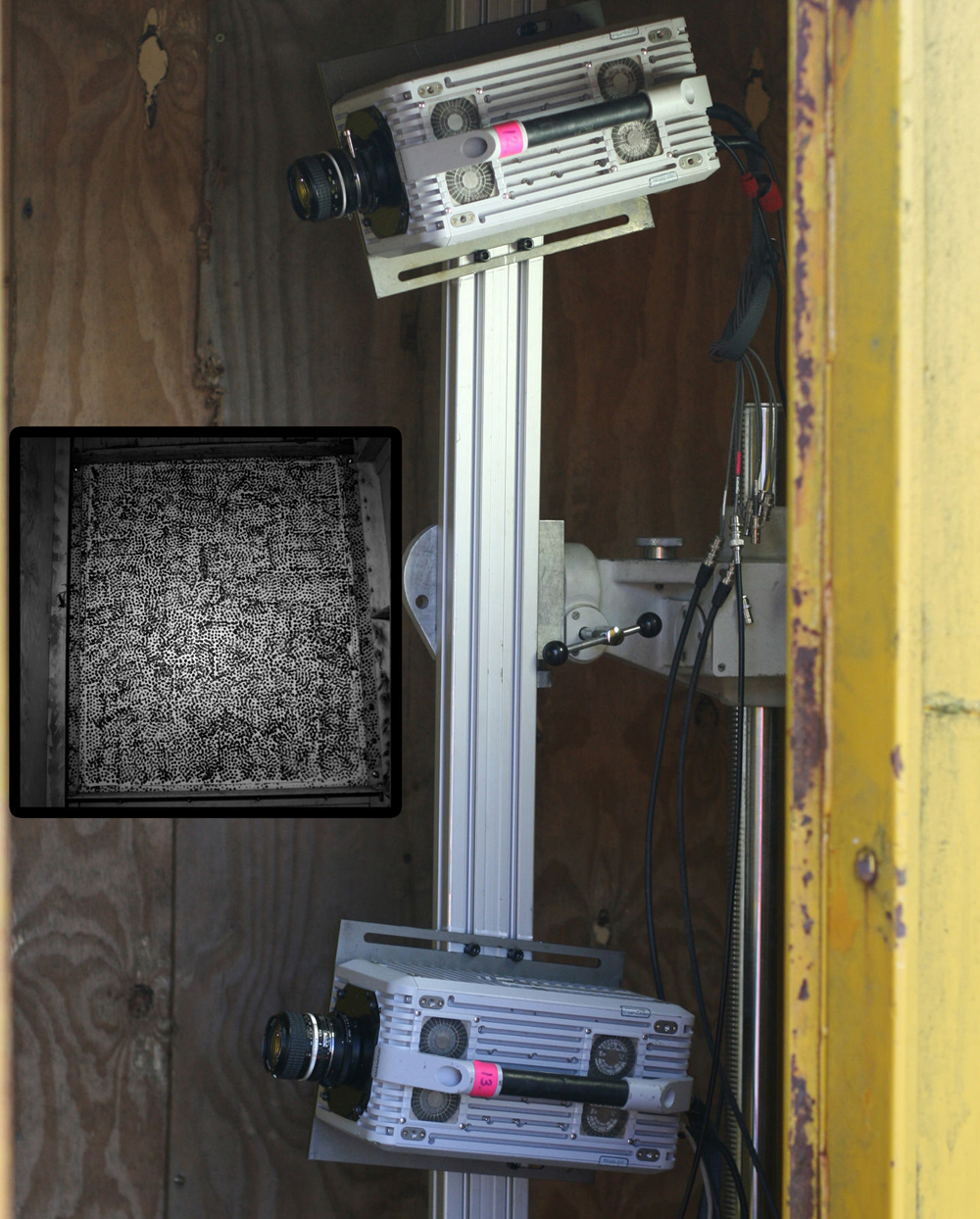

Photron SAX2 mono high speed cameras in position on 3D camera mount (supplied by GOM). Inset – view of speckled plate.

Photron SAX2 mono high speed cameras in position on 3D camera mount (supplied by GOM). Inset – view of speckled plate. Photron SAX2 high speed cameras in position on 3D DIC rig. Inset – view of speckled panel.

Photron SAX2 high speed cameras in position on 3D DIC rig. Inset – view of speckled panel.